Global Leader in Turn-Key Food Processing Solutions

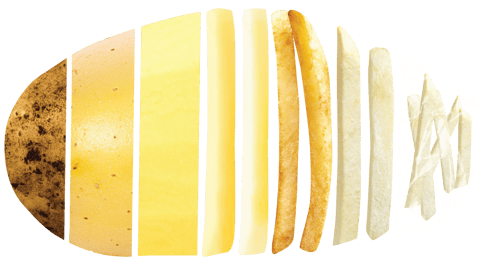

End-to-End Potato Processing Solutions

FPS offers a “one stop shop” to meet customers’ needs with our full line End-to-End solutions. With the addition of CMP of Prince Edward Island and GEM Equipment of Oregon, the FPS Global Family supports every stage of food processing, from raw receiving and frying to freezing and packaging. In addition, our partner OptiCept Technologies brings game-changing Pulsed Electric Field (PEF) technology to the table for optimizing your product for higher yield, raw property extraction and increased sustainability.

The Importance of Hygiene in the Potato Factory: Offsetting Costs, Elevating Uptime

Across the Middle East and Africa (MEA), the demand for processed potato products is rising fast - driven by urbanization, population growth, and evolving consumer diets. As processors expand capacity to meet this demand, they face mounting pressure to uphold international food safety standards while contending with regional realities: high temperatures, fluctuating humidity, and limited access to clean water...

Mourade El Hassouni

General Manager - MEA, FPS

FOODTECH SUMMIT 2025

Establishing Effective Food Quality and Food Safety Management Systems to Mitigate Risk, Maintain Compliance, and Enhance Consumer Confidence

Date: 04-Nov-2025

Time: 14:35 - 15:15

Location: AI Multaqua Ballroom

Mourade El Hassouni, General Manager, MEA, will be joining a panel of experts to highlight the importance of food safety in the food manufacturing sector, most notably in the hygienic design of food processing equipment. In addition, with greater attention to reducing general labor, reducing waste and costly operational mistakes, the move to implement remote monitoring has become even more prominent. Join Mourade as he highlights the benefits of food safety, hygiene, and critical data at the top of any food manufacturer's list.

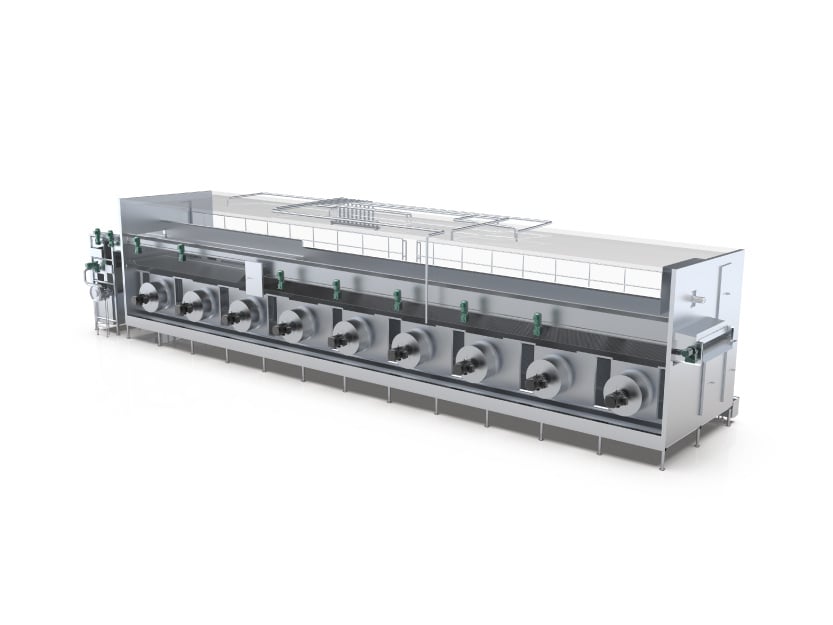

Freezers + Chillers

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands.

We offer a range of innovative technologies for maximizing performance and ensuring the highest hygienic standards, all integral aspects to lowering total cost of ownership. They include Spiral Freezers, IQF Tunnels, Impingement Freezers, French Fry Tunnels, Carton Continuous Flow (CF) MultiPass Freezers, Variable Retention MultiPass (VRM) Freezers and the Spiral Immersion System (SIS)™.

Service & Retrofit

Our retrofit specialists are not only experts with our equipment, but also equipment from other suppliers. We offer comprehensive retrofit packages from systems evaluations to complete structure and enclosure rebuilds. With recent global attention on environmentally friendly practices and food safety concerns, your existing equipment can be evaluated and upgraded to energy efficient operation and meet current hygienic demands.

With constant changes in the market, we understand the importance of keeping up in terms of processing technologies, products and recipes.To ensure your existing equipment can match these new needs with major re-investment, we offer retrofit services to ensure the equipment is optimized for your demands.

Extend Your Run Time

Increase Energy Efficiency & Cost Effective Production

Extend the Life of Your Equipment

Improve Hygiene & Meet Sanitary Design Principles