Freezers + Chillers

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands.

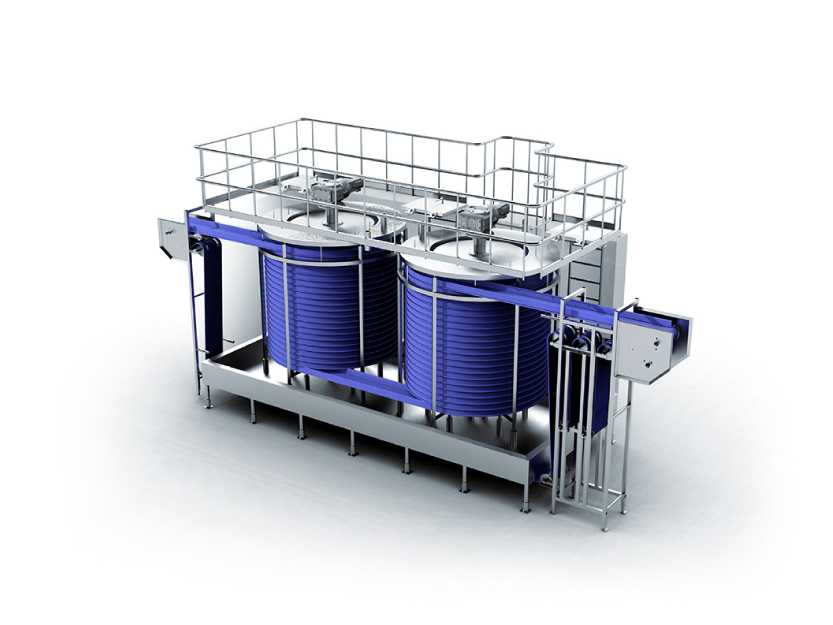

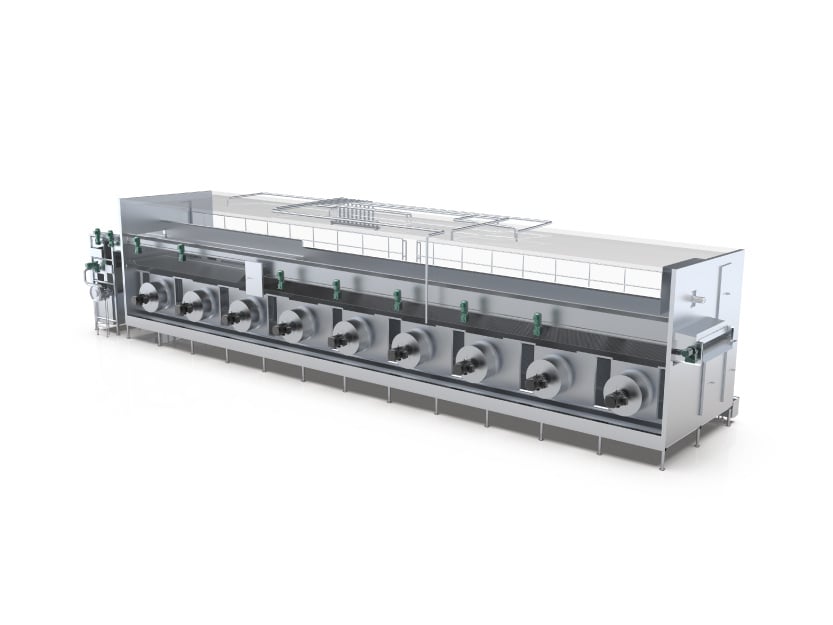

We offer a range of innovative technologies for maximizing performance and ensuring the highest hygienic standards, all integral aspects to lowering total cost of ownership. They include Spiral Freezers, IQF Tunnels, Impingement Freezers, French Fry Tunnels, Carton Continuous Flow (CF) MultiPass Freezers, Variable Retention MultiPass (VRM) Freezers and the Spiral Immersion System (SIS)™.

Conveyance + Product Handling Solutions

We provide innovative, hygienic product and material handling solutions to complement full processing lines. We ensure customers’ products are moved efficiently and hygienically through every step of the production process, from simple conveyors to more complex product handling solutions, to complete raw receiving areas, to frozen grading/packaging.

Thermal Solutions

We offer a wide range of cooking, sous-vide, heating, cooling, and freezing solutions to complement our other offerings. Along with our patented Spiral Immersion System (SIS)™, our solutions include atmospheric steam cookers, brine coolers and freezers, water bath chillers, batch and continuous sous vide cooking systems, batch and continuous cookers, continuous brine chillers and freezers, and packaged meat product chillers.

In Booth Product Demonstration

FPS Remote Servicing (RMS/MES)

Location: FPS Food Process Solutions, Hall 9.0, Stand F20

Customers in the food processing industry demand not only labor and equipment efficiency in freezer operations but assurance in freezer maintenance. Troubleshooting capabilities that are more cost effective are also in high demand, forcing this growing trend in remote servicing.

FPS Food Process Solutions provides two innovative solutions to meet these needs:

- FPS Remote Monitoring System (RMS): A web-based, universal platform that enables customers to track, analyze, and report on freezer performance. The system provides customers with critical data-rich information, giving them the power to make decisions quickly based on reporting history and real-time trends.

- FPS Manufacturing Execution System (MES): Designed to optimize production efficiency, FPS MES bridges the gap between freezer operations and overall manufacturing processes. Combined with the RMS, it not only provides real-time data on equipment performance and production output but work order tracking and scheduling across the plant as well.

Both systems empower the food processing industry with the tools needed to enhance operational efficiency, reduce downtime, and improve overall equipment effectiveness (OEE). All customer information is confidential and secure on the platform and available anywhere in the world. Onsite demos are scheduled throughout tradeshow hours from May 3 – 8, 2025 in Hall 9.0, Stand F20. 15-minute demos (Morning/Afternoon Sessions).

Service and Retrofit

Experience tells you the importance of efficient and responsive service - FPS has you covered. Our 24-hour support hotline puts you in direct contact with a real-world technician, not just an answering service. With the largest freezer service team and spare parts inventory in the industry, FPS support can assist in getting your equipment back in production with minimal disruption.