Global Leader in Turn-Key Food Processing Solutions

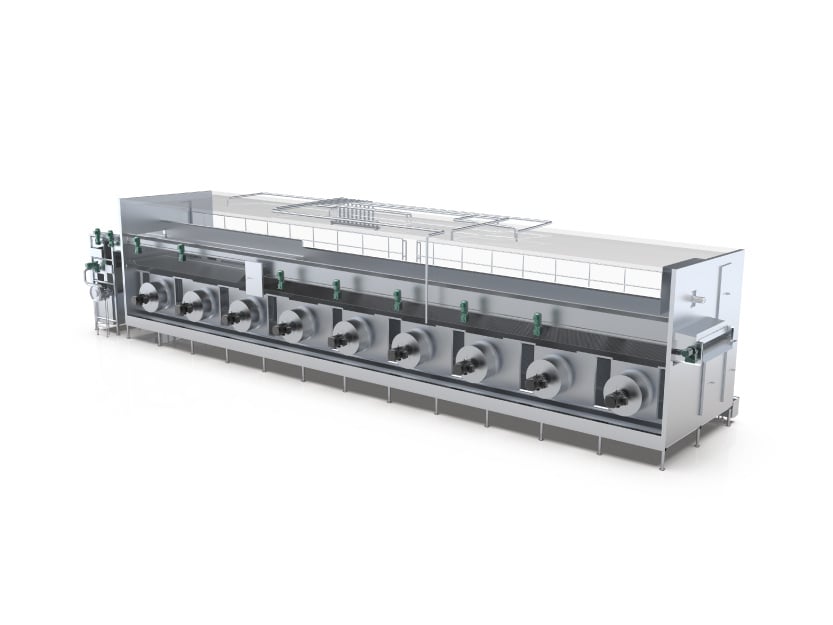

Freezers + Chillers

FPS Food Process Solutions is a global leader in turn-key food processing solutions. We provide innovative systems to ensure the highest efficiencies and to meet the most stringent sanitary demands.

We offer a range of innovative technologies for maximizing performance and ensuring the highest hygienic standards, all integral aspects to lowering total cost of ownership. They include Spiral Freezers, IQF Tunnels, Impingement Freezers, French Fry Tunnels, Carton Continuous Flow (CF) MultiPass Freezers, Variable Retention MultiPass (VRM) Freezers and the Spiral Immersion System (SIS)™.

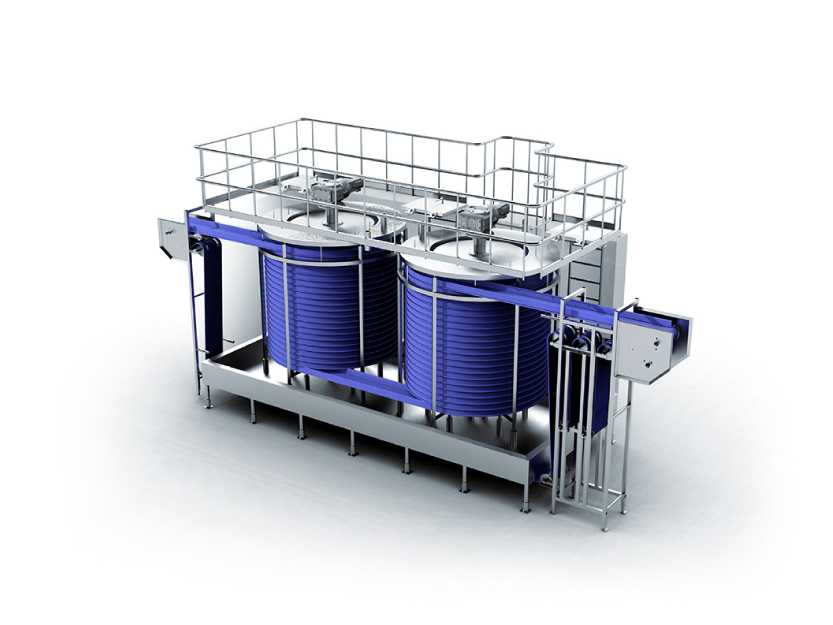

Pulsed Electric Field (PEF) Systems

The OPTICEPT® (Controlled Environment Pulsed Electric Field), is a state-of-the-art PEF-system developed by FPS Food Process Solutions in collaboration with PEF-specialists OptiCept Technologies. Developed into S-Series and L-Series for solid and liquid food processing respectively, the versatile PEF treatment can be applied to a wide range of products.

Live demos will be presented at FPS Food Process Solutions in Stand AX52. Drop by our booth to discover whether PEF is the right fit for your product and how it can help optimize your food processing goals!

Conveyance + Product Handling

We provide innovative, hygienic product and material handling solutions to complement full processing lines. We ensure customers’ products are moved efficiently and hygienically through every step of the production process, from simple conveyors to more complex product handling solutions, to complete raw receiving areas, to frozen grading/packaging.

Fryers

Custom designed fryers and fryer systems are based on customer requirements - there are no two alike. Demonstrating engineering ingenuity with safety and maintenance in mind, GEM designs, builds and installs single and two-stage fryers based on small to large throughout capacity.

At GEM, every fryer is designed using Computational Fluid Dynamics (CFD) to optimize oil flow inside the fryer, while maintaining minimum oil volumes. This ensures first in, first out, and eliminates eddies and dead areas inside the kettle.